At Purbeck we pride ourselves in our capabilities, these include:

* Two factories capable of high-volume production.

* Standard 20 days lead time, with 10 days fast turn arounds.

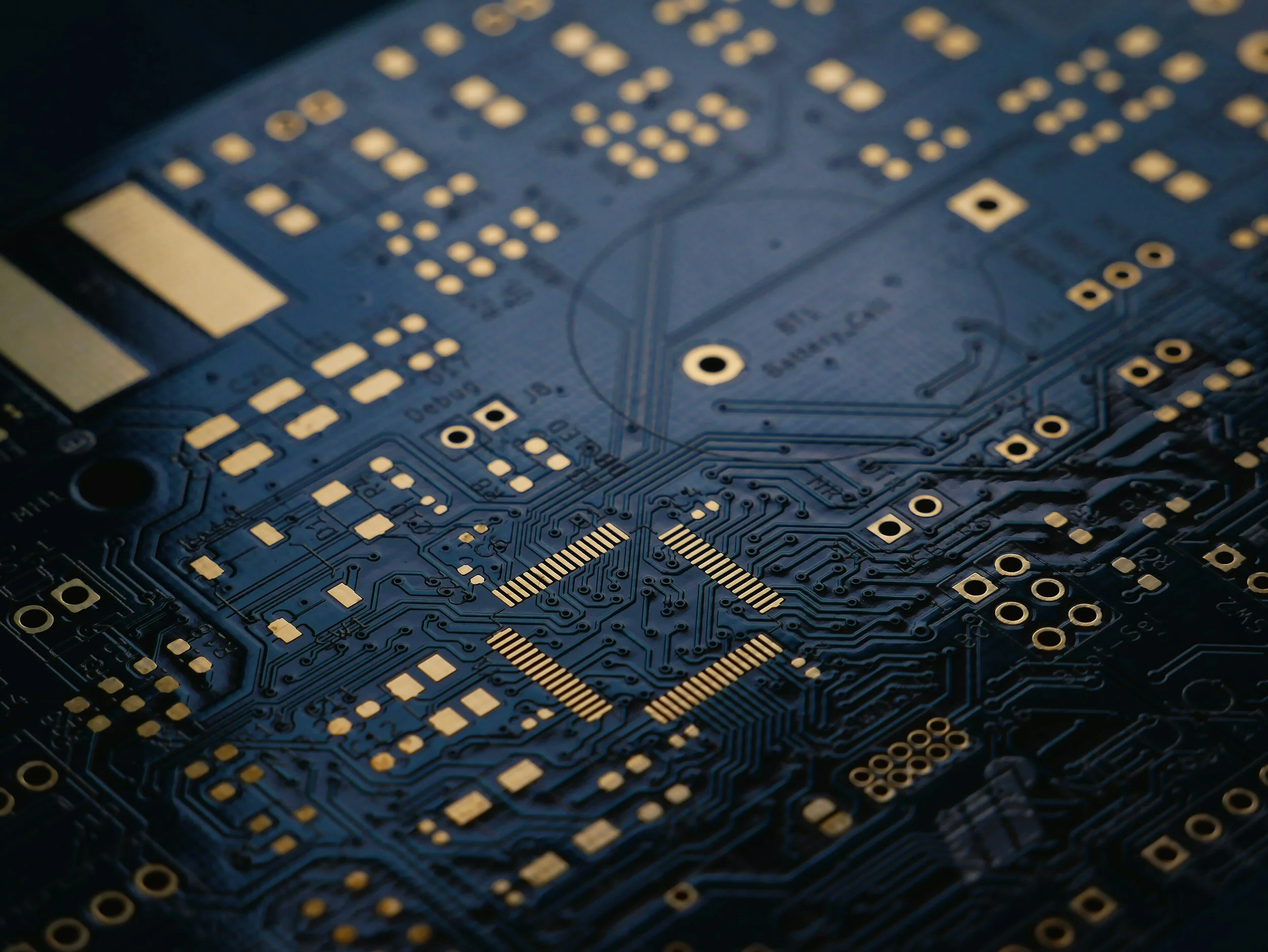

* Surface mount capability of over 500,000 component placements an hour. 5 production lines with Panasonic, Hitachi, and Philips machines.

* We can place any industry standard components, as well as non-standard components.

* 3D AOI Inspection, capable of micron measurement.

* Fully automatic conformal coat.

* Automatic Test Equipment (ATE) and functional test capabilities.

* Large Thru-hole insertion and hand assembly department.

* Full hand built and Machine built prototypes. Can be built in as little as 5 days.

* X-Ray machine that allows us to inspect BGA, track damage, blank ICs and more.

* Environmental Chamber for testing of assemblies (-70ºC to 180ºC, 10% to 98% RH)

* Full Box Build Assembly, including testing, potting, and packing of final assemblies.

* ISO9001 accreditation – Approved for ATEX products assembly.

* Materials purchase – Free quotation.

* High volume runs competitively priced with China.

* Design input for new products – Problem solving for manufacture.

* Good communication with customers – Helping them get the most out of their product.

* First time deals with new customers for larger orders.