Purbeck Electronics is proud to offer a comprehensive range of capabilities, including:

* Dual Manufacturing Sites: Two dedicated factories equipped for high-volume production.

* Efficient Lead Times: Standard 20-day lead time with expedited 10-day turnaround available.

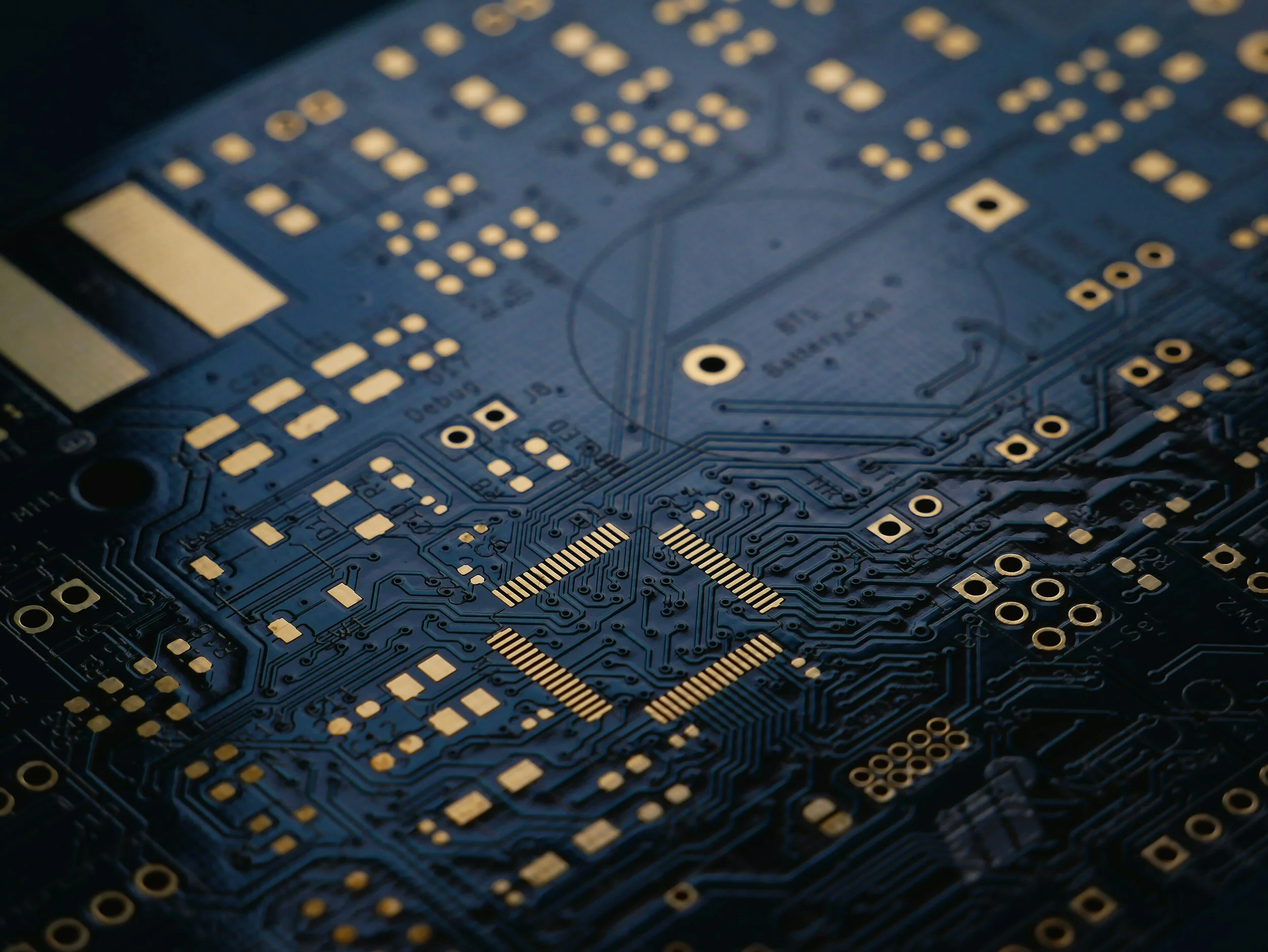

* High-Speed SMT Assembly: Over 500,000 component placements per hour across five production lines using Panasonic, Hitachi, and Philips equipment.

* Versatile Component Placement: Capable of placing all industry-standard and many non-standard components.

* Advanced Optical Inspection: 3D AOI systems with micron-level measurement accuracy.

* Automated Conformal Coating: Fully automatic systems ensuring consistent, high-quality protection.

* Comprehensive Testing: Equipped with Automatic Test Equipment (ATE) and full functional testing capabilities.

* Thru-Hole Assembly Expertise: Dedicated department for high-volume hand and machine insertion.

* Rapid Prototyping: Hand-built and machine-built prototypes delivered in as little as 5 days.

* X-Ray Inspection: High-resolution imaging for BGA, trace integrity, and component validation — including blank IC detection.

* Environmental Stress Testing: In-house chamber simulating conditions from -70°C to +180°C and 10% to 98% relative humidity.

* Complete Box Build: End-to-end assembly including potting, testing, and final packaging.

* Certified Quality: ISO 9001 accredited and approved for ATEX-compliant product assembly.

* Material Procurement: Flexible sourcing and free, no-obligation quotes available.

* Global Pricing Competitiveness: High-volume UK runs priced to compete with offshore alternatives.

* Design & Engineering Support: Expert input for new product introduction and manufacturability improvements.

* Customer Collaboration: Open communication and a problem-solving mindset to help optimize your product.

* Exclusive Offers for New Clients: Special pricing available on large initial orders.